The energy transition towards a secure, competitive and decarbonised energy system is one of the major environmental challenges currently facing the energy intensive industries of the EU.

The BAMBOO project (Boosting newApproaches for flexibility Management By Optimizing process Off-gases andwaste use) was created to help industries overcome these challenges. Headed up by CIRCE, the Research Centre for Energy Resources and Consumption, the projectwill develop solutions including electrical flexibility,waste heat recovery andwaste-to-energy streams thatwill improve the competitiveness of industry.

The project will work to validate different innovative technologies that will be the key to making the most of currently unused waste streams in addition to introducing biomass fuels into the productive process. In this way the flexibility of the energy supply will be enhanced and consumption and dependency on fossil fuels reduced, while improving energy saving.

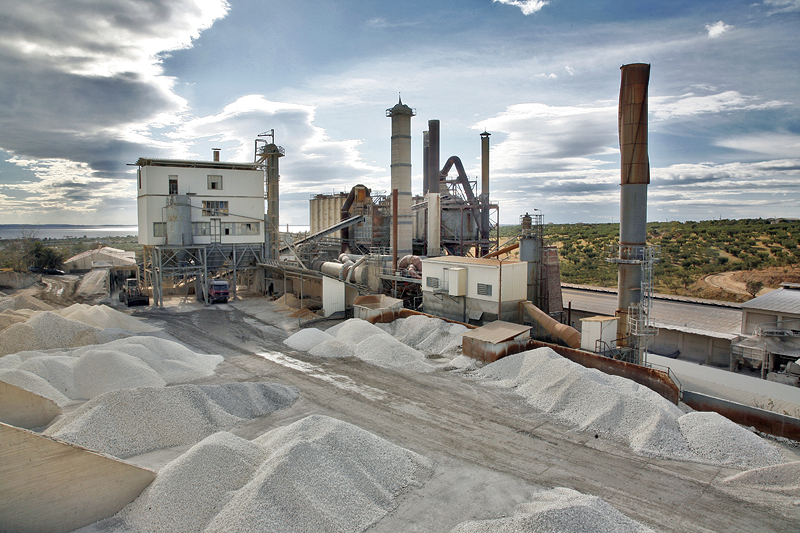

To achieve this goal, the 19 BAMBOO partners will spend four years working to develop innovative technologies that will be adapted, tested and validated under real production conditions at four intensive industries in Europe: steel company Arcelor Mittal (Spain), mining company Grecian Magnesite (Greece), pulp and paper company UPM (Germany) and petrochemical company Tüpras (Turkey). The new technologies implemented will address the challenges of energy efficiency and resources and will focus on three main pillars of innovation: residual heat recovery, electrical flexibility and waste-to-energy streams. As a result, BAMBOO hopes that industries will be able to cut their costs by between 16% and 20%, improve energy efficiency by 18% and reduce CO2 emissions by 5%.

As project coordinator, last March Fundaciòn CIRCE hosted the first general meeting of BAMBOO at its head offices in Zaragoza at which the next steps and goals to be achieved during the coming year were defined. The consortium also defined operational activities and strategies by drawing up an initial market analysis and identifying models and business plans for the development of outcomes. Within the field of electrical flexibility, BAMBOO will develop an innovative hybrid process capable of working with residual heat, steam or electricity. This will allow flexible operating strategies to be deployed so that the plant can benefit from the lowest energy prices. In the area of waste heat recovery, the project will roll out technologies and processes that enable both its internal reutilisation and the introduction of alternative streams. In particular, it will work towards validating advanced process gas combustion monitoring techniques, developing technologies that will allow the use of biomass as an alternative fuel.

As regards residual heat recovery, BAMBOO will develop technologies to recover the energy content that is usually lost in order to use it at other points of the productive process itself where demand exists. These three pillars will be contained within a flexibility tool that will work transversally to improve industrial competitiveness. This tool is easy to replicate, given that its analysis and actions can be adapted to the peculiarities of each plant. As such, it obtains information and produces forecasts on the energy market and the flows of electricity, heat and materials of the industrial processes. It represents a major support for decision-making in order to better manage flexibility at industrial level and help industries handle different flows of energy and materials. Specifically, the tool will be able to optimise the management of plant operations in real time, in terms of programming processes, the reutilisation of flows and purchases of energy and raw materials, recommending investments to improve the flexibility potential of the plan based on the return on investment of these actions.

BAMBOO also sets out to cover real needs relating to the monitoring, control and optimisation of the combustion processes arising from the use of alternative fuels. The project aims to improve the flexibility of the combustion systems, which results in significant savings of up to 19% in energy costs, raw materials consumption and emissions, for which BAMBOO will develop new advanced combustion techniques. Thus an innovative combustion diagnostic tool, based on the image of the flame and a multi-fuel, low NOx burner, will allow plant operators to optimise the monitoring, control and operation of the burner as well as maximise the substitution of fossil fuels with other alternatives. CFD simulations will also be carried out to complement the diagnostic model and to gain a better understanding of the behaviour of combustion in industrial ovens and boilers. The project aims to develop and test a high temperature heat pump in the steel industry. This unit will use the residual heat from the steel cooling process to produce saturated steam at 5 bar, which will enable up to 20% of the residual heat produced at low temperature to be recovered. This steam can then be used to cover internal demand or sold to nearby industries that need steam for their processes. The implementation of this solution will result in a 9% reduction in fossil fuel consumption. Similarly, BAMBOO aims to demonstrate at industrial level a technology based on the Ranking Organic Cycle, which substitutes water for an organic fluid and enables the cycle change to take place at a lower temperature, allowing low temperature heat recovery and power generation. Specifically, the project will develop a heat exchanger capable of working with more than one heat source, enabling the residual heat to be recovered and generating electricity for use inside the plant.

This system will recover 30% of the residual heat with a 5% associated saving in terms of electricity consumption and emissions. Moreover, the combination of this technology (to generate electrical power) and heat pumps (for thermal uses) aims to provide intensive industries with additional energy options and resource flexibility, leading to a more efficient use of energy flows, heat recovery and raw materials. With a view to facilitating the integration of renewable energy into industrial processes and adapting them to fluctuating inputs, BAMBOO will apply the concept of hybrid heating to develop a drying process to recover organic waste sludge from the paper and pulp industry in order to produce a biofuel, with the ultimate aim of replacing fossil fuels and reducing emissions. This drying process will take place using steam, residual heat or electricity depending on its availability and price, fully recovering all the sludge generated and improving the flexibility of the system. BAMBOO will also create a training development programme to transfer the knowledge acquired during project implementation to the managers and employees of industrial plants so that they can exploit the potential for flexibility in their processes. In short, the potential for transfer of BAMBOO is extremely significant given that the specific processes and plant improvements offer applications that have great potential in other intensive industries.

Article by FuturEnergy, featured in the issue of May, downloadable here.