Due to its significant resource use, its waste and emissions, heavy industry has for many years been seen as an obstacle to sustainable development. But this is not the full story. Today the resource energy intensive industries (REII) must adapt their current consumption and production patterns to a higher share of renewable energy supply. In this new scenario, industrial plants need access to better information and new technologies to enable higher flexibility on electricity supply while decreasing the consumption and dependence on fossil fuels.

How will BAMBOO contribute to improving industrial flexibility?

BAMBOO is expected to demonstrate energy and materials demand management concepts in highly intensive industries relying on the valorisation and reuse of waste streams. BAMBOO solutions will make REII more sustainable as they will improve the energy efficiency of the processes while enabling a better management of the energy sources.

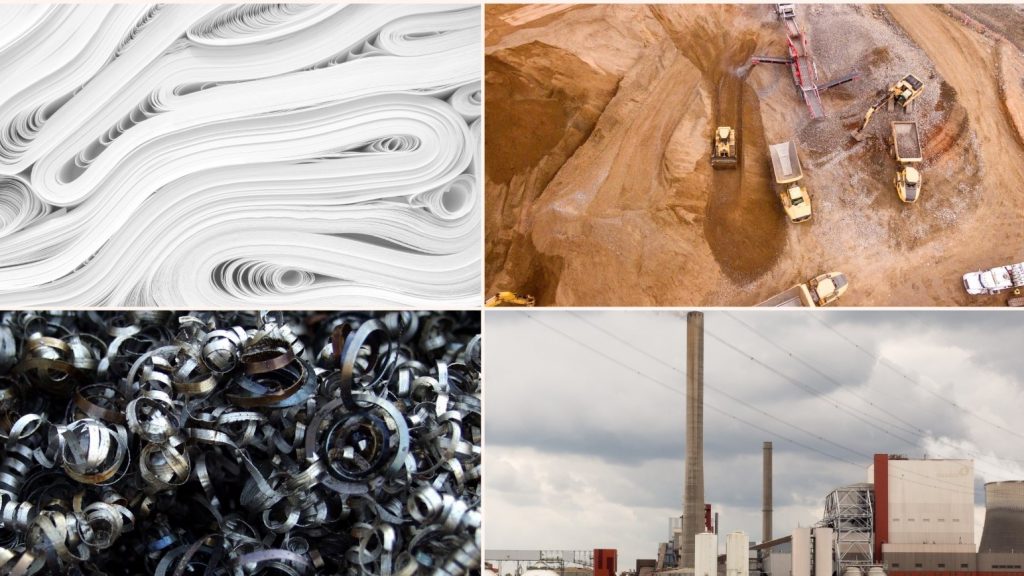

BAMBOO’s technologies will be demonstrated in four European plants:

- Steel (Areclor Mittal, Spain): Advanced flame monitoring system and heat pump for waste heat recovery

- Minerals (Grecian Magnesite, Greece) Adaptation of current burner to multi-fuel low-nox burner

- Paper & Pulp (UPM, Germany): Novel trivalent dryer to valorize biosludge and to improve flexibility

- Petrochemical (Tupras, Turkey): Waste heat recovery by means of a novel heat exchanger for an orc system

Download the BAMBOO brochure to learn more about teh project, its expetcted impact and the field demonstration.

Every industrial process is also represented through a dedicated infographic.